-

Underground Concrete Mixer

This vehicle is specially designed for underground mining, there are different type, horizontal and Inclined concrete drum. Generally speaking, horizontal type is for 2~4m3 concrete drum while the inclined type is for 5~8m3.

-

Underground Oil Tanker

This vehicle is used to transport fuel, hydraulic fluid, engine oil, gear oil to underground. The tank quantity and volume can be made as per client requirement.

-

Underground Explosive Loader

This vehicle is used to put explosives to the blast hole. The equipment must be explosion-proof.

-

Underground Explosive Vehicle

This vehicle is used to transport explosives to the mine. The equipment explosives box, electrical system, etc. must be explosion-proof.

-

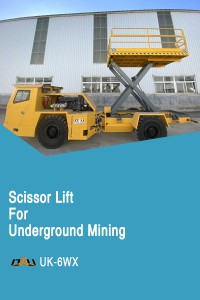

UK-6WX Underground Scissor Lift: The Perfect Solution for Lifting Heavy Loads

The UK-6WX Scissor Lift is a high-performance lifting equipment that is designed to meet the demands of heavy-duty lifting in underground spaces. With a lifting capacity of up to 3.5 meters, this scissor lift is ideal for a wide range of applications, including mining, construction, and maintenance operations.

One of the key features of the UK-6WX Scissor Lift is its compact design that allows it to fit into tight spaces. This makes it the perfect solution for lifting heavy loads in underground spaces where there is limited room for maneuvering. The lift is also equipped with a powerful hydraulic system that provides smooth and efficient lifting, making it easy to handle heavy loads with precision and control.

The UK-6WX Scissor Lift is built to withstand the harsh conditions of underground environments. It is constructed with high-quality materials that are resistant to corrosion, wear, and tear.

In addition to its impressive lifting capacity, the UK-6WX Scissor Lift is also designed for ease of use. It features a user-friendly control panel that allows operators to adjust the lift’s height and direction with ease.

Overall, the UK-6WX Scissor Lift is a reliable and efficient lifting solution for underground operations. Its compact design, powerful hydraulic system, and safety features make it the perfect choice for lifting heavy loads in tight spaces. Whether you are working in mining, construction, or maintenance, the UK-6WX Scissor Lift is sure to meet your lifting needs.

-

Durable Mining Machinery: The Underground Lift Table Mining Scissor-Lift Platform Vehicle

Introduction:

In the mining industry, the need for durable and reliable machinery is crucial to ensure efficient and safe operations. One such machinery that plays a vital role in underground mining is the lift table mining scissor-lift platform vehicle. This article explores the importance of durable mining machinery, particularly focusing on the underground lift table mining scissor-lift platform vehicle.1. Understanding the Underground Lift Table Mining Scissor-Lift Platform Vehicle:

The underground lift table mining scissor-lift platform vehicle is a specialized piece of equipment designed for transporting heavy loads and personnel in underground mining environments. It features a scissor-lift mechanism that enables vertical movement, providing access to different levels within the mine. This vehicle is specifically built to withstand the harsh conditions and challenges encountered in underground mining operations.2. Durability: A Critical Factor in Mining Machinery:

Durability is a critical factor in mining machinery due to the demanding nature of mining operations. Underground mining environments are characterized by extreme temperatures, high humidity, dust, and vibrations, which can put significant strain on equipment. Durable machinery can withstand these conditions, ensuring minimal downtime and reducing maintenance costs.3. Importance of Durable Lift Table Mining Scissor-Lift Platform Vehicle:

The lift table mining scissor-lift platform vehicle’s durability is of utmost importance in underground mining. It must withstand heavy loads, constant movement, and exposure to dust and debris. A durable vehicle ensures the efficient transportation of personnel and materials, reducing the risk of accidents and increasing productivity.4. Key Features of a Durable Lift Table Mining Scissor-Lift Platform Vehicle:

a. Robust Construction: The vehicle should be constructed using high-quality materials that can withstand the rugged mining environment.

b. Corrosion Resistance: Underground mining environments often have high levels of moisture and corrosive elements. A durable vehicle must have effective corrosion-resistant coatings.

c. Enhanced Safety Features: Durable vehicles should be equipped with safety features such as emergency stop buttons, anti-slip surfaces, and reliable braking systems to ensure the safety of personnel.

d. Easy Maintenance: Durable machinery should be designed for easy maintenance, allowing for regular inspections and repairs without causing significant downtime.5. Benefits of Using Durable Mining Machinery:

a. Increased Productivity: Durable machinery minimizes downtime due to breakdowns or maintenance, ensuring continuous operations and increased productivity.

b. Cost Savings: Investing in durable machinery reduces repair and replacement costs, leading to long-term cost savings.

c. Enhanced Safety: Durable machinery provides a safe working environment, reducing the risk of accidents and injuries to personnel.Conclusion:

In the demanding mining industry, the durability of machinery is paramount. The underground lift table mining scissor-lift platform vehicle plays a crucial role in underground mining operations, providing safe and efficient transportation of personnel and materials. Choosing a durable vehicle ensures uninterrupted operations, increased productivity, and a safer working environment. -

Unveiling our Game-Changing 40 Ton Articulated Underground Mining Truck

We are thrilled to announce that our highly anticipated 40-ton articulated underground mining truck has completed its production and is now ready for testing and debugging. This remarkable achievement marks a significant milestone for our company and reinforces our commitment to delivering cutting-edge technology to the mining industry.

The development of this 40-ton articulated underground mining truck has been a laborious and meticulous process. Our engineering team has dedicated countless hours to designing and refining every aspect of this powerful machine to ensure optimal performance and safety in the harsh underground mining environment.

With a payload capacity of 40 tons, this articulated underground mining truck is specifically designed to handle the demanding tasks of underground mining operations. Its robust construction and advanced features make it capable of navigating through narrow tunnels and rugged terrains, ensuring efficient transportation of minerals and materials.

The articulated design of the truck allows for enhanced maneuverability and flexibility, enabling it to navigate tight corners and confined spaces with ease. This feature is crucial in underground mining operations where space is limited, and maneuvering heavy machinery can be challenging.

Safety has always been a top priority in our product development. Our 40-ton articulated underground mining truck is equipped with state-of-the-art safety features. These features are designed to minimize the risk of accidents and enhance the overall safety of the mining operation.

Before the truck is deployed for commercial use, it will undergo rigorous testing and debugging. Our team of experts will meticulously inspect and evaluate every component of the truck to ensure its reliability and performance. This testing phase is essential to identify any potential issues or areas that require improvement, guaranteeing that the truck meets the highest standards before it reaches our valued customers.

We are confident that our 40-ton articulated underground mining truck will revolutionize the mining industry with its exceptional performance and advanced features. Its efficient operation and enhanced safety features will significantly improve productivity and reduce downtime in underground mining operations.

As we move forward with the testing and debugging phase, we remain committed to providing the mining industry with innovative solutions that optimize productivity, enhance safety, and minimize environmental impact. Our 40-ton articulated underground mining truck is a testament to our dedication to pushing the boundaries of technology and delivering superior products to our customers.

In conclusion, the completion of our 40-ton articulated underground mining truck is a significant achievement for our company. We are excited to enter the testing and debugging phase and look forward to introducing this groundbreaking machine to the mining industry. With its exceptional performance, advanced features, and unwavering commitment to safety, we believe that our truck will set new standards in underground mining operations.

-

multifunction underground utility for Scissor Lift

The DALI Scissor Lift with lifting capacity up to 4.5 tonnes and max platform height of 4.5 m is designed to provide a safe work platform for all kinds of installation works in tunnels up to 6.5 m (21 feet) high. Typical applications are fan installations, ventilation ducting, electrification works and piping for air and water services. Four platform sizes with side shift provide complete drift coverage from single setup practically in all kinds of mine headings.

-

Introducing the UK-40: Our Latest Innovation in Underground Mining Trucks

We are excited to introduce our newest addition to the underground mining industry – the UK-40. With a new, robust, and structurally optimized design, along with a powerful diesel engine system, this truck is purpose-built for the demanding environment of underground mining.

The UK-40 has been engineered to provide exceptional performance and durability, ensuring maximum productivity and efficiency in mining operations. Its innovative design incorporates the latest advancements in technology and materials, making it a reliable and cost-effective choice for mining companies.

One of the standout features of the UK-40 is its impressive payload capacity of 40 tons. This means it can carry a substantial amount of material, reducing the number of trips required and increasing overall productivity. With its high load capacity, the UK-40 is capable of transporting large quantities of ore, minerals, or waste material from the mining face to the surface efficiently.

The robust design of the UK-40 ensures its ability to withstand the challenging conditions of underground mining. It is built to endure the constant vibrations, rough terrain, and extreme temperatures commonly encountered in these environments. The truck’s reinforced frame and heavy-duty components guarantee its longevity and reliability, minimizing downtime and maintenance costs.

Equipped with a powerful diesel engine system, the UK-40 delivers excellent performance and fuel efficiency. The engine is designed to meet the specific requirements of underground mining, providing the necessary power and torque to handle steep inclines and heavy loads. Its advanced emissions control technology ensures compliance with environmental regulations, making the UK-40 an environmentally friendly choice.

Safety is a top priority in the mining industry, and the UK-40 is equipped with a range of safety features to protect operators and enhance operational safety. The truck is fitted with state-of-the-art monitoring systems, including cameras and sensors, to provide operators with real-time information about their surroundings. Additionally, the UK-40 is designed with ergonomic controls and comfortable seating, ensuring operators can work efficiently and safely throughout their shifts.

In conclusion, the UK-40 sets a new standard for underground mining trucks. Its robust and structurally optimized design, combined with a powerful diesel engine system, offers exceptional performance, durability, and efficiency. With a 40-ton payload capacity, this purpose-built truck is ready to tackle the demanding challenges of underground mining. Invest in the UK-40 and experience the difference in productivity and profitability it can bring to your mining operations.

-

Underground Scissor Lift

The DALI Scissor Lift with lifting capacity up to 4.5 tonnes and max platform height of 4.5 m is designed to provide a safe work platform for all kinds of installation works in tunnels up to 6.5 m (21 feet) high. Typical applications are fan installations, ventilation ducting, electrification works and piping for air and water services. Four platform sizes with side shift provide complete drift coverage from single setup practically in all kinds of mine headings.