Mining Equipment Mini 0.6CBM 4WD Underground Diesel LHD Scooptram

The WJ-0.6 is full of features to help mines maximize tonnes and minimize extraction costs. Engineered to optimize machine width, length and turning radius, enabling operation in narrower tunnels for less dilution and lower operational costs.

Technical Specification

|

Dimension |

Capacity |

||

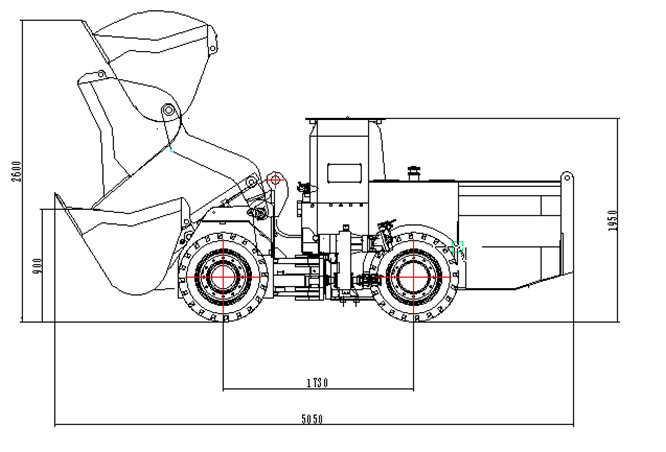

| Tramming Size | 5050*1150*1950mm | Standard Bucket | 0.6m3(0.5 option) |

| Min Ground Clearance | 220mm | Payload | 1200KG |

| Max Lift Height | 2600mm | Max Breakout Force | 35KN |

| Max Unloading Height | 900mm | Max Traction | 40KN |

| Climing Ability(Laden) | 20° | ||

|

Performance |

Weight |

||

| Speed | 0~8km/h | Operation Weight | 5135kg |

| Boom Raising Time | ≤2.5s | Laden Weight | 6335kg |

| Boom Lowering Time | ≤1.8s | Front Axle(Empty) | 1780kg |

| Dumping Time | ≤2.1s | Rear axle(Empty) | 3355kg |

| Oscilation Angle | ±8° | Front Axle(laden) | 3120KG |

Power Train

|

Engine |

Transmission |

||

| Brand & Model | Deutz BF4L2011 | Type | Hydrostatic of forward & reverse |

| Type | Air-Cool & Turbocharge | Pump | PV22 |

| Power | 47.5kw / 2300rpm | Motor | MV23 |

| Cylinders | 4 In line | Transfer Case | DLW-1 |

| Displacement | 3.11L |

Axle |

|

| Max Torque | 230Nm/1600rpm | Brand | DALI |

| Emission | EURO II / Tier 2 | Model | PC-15-A |

| Purifier Brand | ECS(Canada) | Type | Rigid planetary axle |

| Purifier Type | Catalytic purifier with silencer | ||

Structure

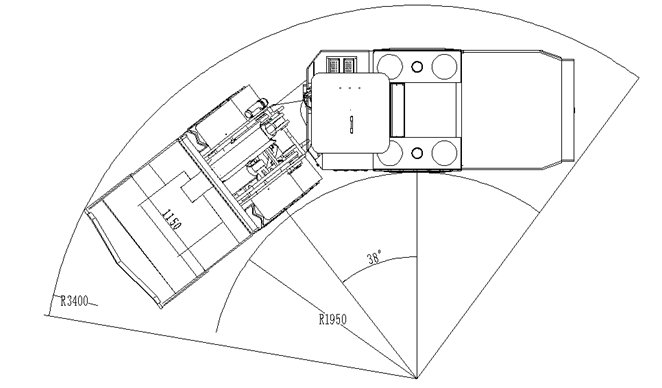

● The frames are articulated with 38° steering angle.

● Ergonomics Canopy with side seat to provide good bi-directional view of operation.

● An enhanced boom and load frame geometry optimizes digging performance.

Power Train

● 4 wheels driving & braking.

● Combination design of parking brake & working brake ensures good braking performance. Braking model is SAHR(spring applied, hydraulic release).

● Front axle is equipped NO-SPIN differential. While rear is ANTI-SLIP.

● Hydraulic joystick control for working to reduce the labor intensity of the driver.

● Low vibration level in cab

Early Warning & Maintenance

● Automatic alarm system for oil temperature, oil pressure and electrical system.

Enegy-saving & Enviroment Friendly

● Germany Deutz engine with air-cooling and turbocharging, powerful and low-consumption.

● Canada ECS catalytic purifier with silencer, which greatly reduces air and noise pollution in working laneway.