Durable Mining Machinery: The Underground Lift Table Mining Scissor-Lift Platform Vehicle

The works can be accomplished safely, efficiently and comfortably from the level work deck, elevated to a optimum work height. Optional remote drive system from the deck brings fully new type efficiency into installation and assembly works in underground mines. The powerful liquid cooled turbo charged Deutz 120 kW or MB 110 kW TIER 3 approved engine provides clean and efficient operation and gives maximum speed of 9 km/h in upward inclined 1:7 tunnel. In horizontal tunnel the maximum speed is 25 km/h. The new DALI FOPS and ROPS approved safety cabin provides superior visibility and comfortable compartment for the driver and the passenger. Cabin is designed for safe and easy entry and exit. Door openings are wide and handrails and non-slip steps are correctly positioned. Dashboard is easy and simple to use. New multifunctional display (MID) provides driving information (speed, RPM, temperatures etc.) and information can be recorded for analysis. Enclosed cabin provides noise level < 75 dB ensuring safe and comfort driving.

Power Train

Engine

Brand……………………….DEUTZ

Model………………………. F6L914

Type………………………...air cooled

Power………………………84 kW / 2300rpm

Air intake system…………..two stage / dry air filter

Exhaust system……………catalyst purifier with muffler

Axle

Brand……………………….DANA SPICER

Model………………………112

Differential…………………Rigid Planetary Axle Design

Rear axle steering angle….±10°

Turning radius

Inside………………………3750mm

Out…………………………5900mm

Brake system

Service brake design……...multi-disc brake

Parking brake design……...spring applied, hydraulic release

Main Parameter

Lifting capacity……………5000kg(platform lowered)

Lifting capacity……………2500kg(with raised platform)

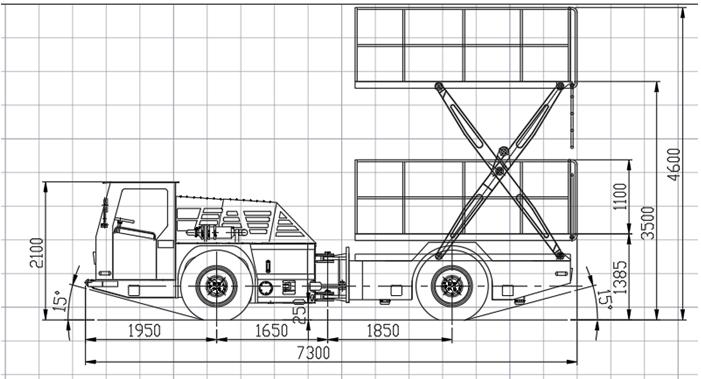

Platform lifting height…….3500mm

Climing ability……………. 25%

Deck dimension…………..1.8m X 3m

Battery

Brand………………………USA HYDHC

Model………………………SB0210-0.75E1 / 112A9-210AK

Nitrogen pressure…………7.0-8.0Mpa

Frame…………………….…..Central articulated

Finger material……………BC12 (40Cr) d60x146

Tire size……………………..10.00-20

Travel speed (forward / backward)

1st gear…………………….6.5km/h

2nd gear……………………13.0 km/h

3rd gear…………………….20.0 km/h

Transmission

Brand……………………….DANA CLARK

Model……………………….1201FT20321

Type………………………...integrated transmission

Dimensions

Length……………………..7300mm

Width……………………....1800mm

Platform Height……………2485mm

Cab Height…………………2100mm

Tire size……………………10.00-R20 L-4S PR14

Hydraulic system

All elements of steering, work platform and braking system - SALMAI tandem gear pump (2.5 PB16 / 11.5)

Hydraulic Components - USA MICO (Charge Valve, Brake Valve).

Frame

Articulated frame, articulated steering, rigid front and rear axles

Articulation stop,

Rigid welded frame made of high quality sheet and profile steel.

Towing lugs located at the front and rear of the machine.

Operator's cab

Closed operator's cab in accordance with ROPS / FOPS safety system Heating and air conditioning of the operator's cab.

Conveniently located controls and controls.

Two rear-view mirrors on the outside of the cab.

With fan and windscreen blower nozzles.

Adjustable driver's seat with shock absorber, seat belt and optional passenger seat

Rear view video system

Consisting of a monitor and one video camera behind the car

Scissor Lift Platform

The mount of the lift to the frame is rigid,

Lifting force: 2.5 t

Lifting capacity of the lowered platform: 5.0 t

Two lifting hydraulic cylinders for lifting the scissor arm, equipped with hydraulic locks that hold the hydraulic cylinder rod in case of a hydraulic hose rupture,

Railings around the platform perimeter.

Supports

Four hydraulic outriggers that extend vertically for increased stability (hydraulic control).

Terms of application

Ambient temperature: -20 ° C - + 40 ° C

Altitude: <4500 m