-

Underground Material Truck

This is utility vehicle for underground mining, can be used for transporting material and handling machines. The crane capacity ranges 500~2000kg with 0~4m distance.

-

Underground Concrete Mixer

This vehicle is specially designed for underground mining, with different types of horizontal and inclined concrete drums. The horizontal type is suitable for 2 to 4 cubic meters of concrete drum, while the inclined type is designed for 5 to 8 cubic meters.

On the other hand, the inclined concrete drum is designed for larger mining operations that demand a higher capacity of 5 to 8 cubic meters. The inclined design allows for efficient pouring of concrete at various angles and locations within the mine. This type of vehicle is suitable for mines with larger tunnels and the need for a higher volume of concrete transportation.

Both types of vehicles are equipped with advanced features to enhance safety and productivity. They are designed with robust materials to withstand the harsh underground conditions. The vehicles are also equipped with powerful engines and reliable braking systems to ensure smooth and controlled movements within the mine.

Furthermore, these vehicles are equipped with advanced control systems that provide operators with real-time information about the concrete drum’s capacity, speed, and other critical parameters. This allows for better planning and management of concrete transportation within the mine.

In conclusion, this specially designed vehicle for underground mining offers different types of horizontal and inclined concrete drums to meet the diverse needs of mining operations. The horizontal type is suitable for smaller volumes, while the inclined type is designed for larger capacities. These vehicles provide efficient and safe transportation of concrete within the mine tunnels, ensuring smooth operations and productivity.

Business type

We are a self-owned factory with years of production and export experience.

Company location

Our factory is situated in Yantai, Shandong Province, China, a location that boasts both a harbor and an international airport. Additionally, it enjoys close proximity to Qingdao Airport and harbor, providing our customers with great convenience for visiting and shipping goods.

Employee headcount

We have over 100 employees, including experienced engineers (R&D, quality inspection, and after-sales), workers, and salespersons. Additionally, we have local salespersons in some countries.

Main markets

Our products are mainly sold to Peru, Chile, Bolivia, Colombia in South America, Russia, and Kazakhstan in the Commonwealth of Independent States, as well as some countries in Africa, Eastern Europe, and Southeast Asia. We participate in exhibitions in these regions and visit local customers to understand the needs of customers in different regions and maintain stable cooperative relationships.

Main products

Underground mining equipment(underground mining scooptram, underground mining truck, underground service vehicle, underground electric locomotive, rock splitter, and underground concrete mixer truck, etc.), mineral processing equipment(crush, feeder, leaching tank, vibrating screen, and shaking table, etc.)) and related accessories and spare parts(engine, converter, transmission, axle, tire, filter, etc.).You can check them on our homepage or contact us for details.

Patents and certifications

We have some practical patents for our products and have passed CE, ISO9001, and other authoritative certifications. You can check them on our homepage or contact us for details.

Equipment maintenance

Underground mining equipment requires regular maintenance to ensure optimal performance and safety. This may involve routine inspections, lubrication, replacement of parts(we recommend you purchase some parts along with the equipment for convenient replacement and low shipping), and repairs as needed. We can provide online maintenance guidelines and support.

More information

To learn more about our company’s information and products, you can follow us on Facebook, Pinterest, YouTube, LinkedIn, Instagram, and VK. You can also browse our website(www.qxdali.com) or contact us through WhatsApp, WeChat, and Telegram.

-

Underground Oil Tanker

This vehicle is used to transport fuel, hydraulic fluid, engine oil, gear oil to underground. The tank quantity and volume can be made as per client requirement.

-

Underground Explosive Loader

This vehicle is used to put explosives to the blast hole. The equipment must be explosion-proof.

-

Underground Explosive Vehicle

This vehicle is used to transport explosives to the mine. The equipment explosives box, electrical system, etc. must be explosion-proof.

-

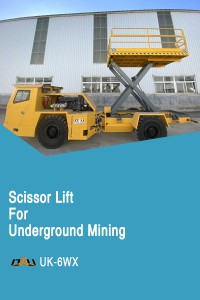

Professional Multifunction underground utility for Scissor Lift

The DALI Scissor Lift is a versatile and reliable piece of equipment designed specifically for installation works in tunnels. With a lifting capacity of up to 4.5 tonnes and a maximum platform height of 4.5 meters, it ensures a safe and efficient work platform for various applications.

One of the main advantages of the DALI Scissor Lift is its ability to accommodate tunnels up to 4.5 meters high. This makes it ideal for a wide range of projects, including fan installations, ventilation ducting, electrification works, and piping for air and water services. Whether it’s a small-scale installation or a larger project, the DALI Scissor Lift can handle the job.

Safety is a top priority when working in tunnels, and the DALI Scissor Lift is designed with this in mind. It is equipped with various safety features, including emergency stop buttons, safety rails, and non-slip platforms. These features ensure that operators can work confidently and securely at heights, minimizing the risk of accidents or injuries.

In addition to its safety features, the DALI Scissor Lift is also known for its durability and reliability. It is built to withstand the harsh conditions often encountered in tunnel environments, including dust, vibrations, and uneven surfaces. This ensures that the scissor lift can perform consistently and efficiently, reducing downtime and increasing productivity.

Overall, the DALI Scissor Lift is a valuable tool for installation works in tunnels. Its lifting capacity, platform height, and versatility make it suitable for a wide range of applications. With its safety features and durability, it provides a secure and efficient work platform for operators. Whether it’s fan installations, ventilation ducting, electrification works, or piping for air and water services, the DALI Scissor Lift is a reliable choice for any tunnel project.

Business type

We are a self-owned factory with years of production and export experience.

Company location

Our factory is situated in Yantai, Shandong Province, China, a location that boasts both a harbor and an international airport. Additionally, it enjoys close proximity to Qingdao Airport and harbor, providing our customers with great convenience for visiting and shipping goods.

Employee headcount

We have over 100 employees, including experienced engineers (R&D, quality inspection, and after-sales), workers, and salespersons. Additionally, we have local salespersons in some countries.

Main markets

Our products are mainly sold to Peru, Chile, Bolivia, Colombia in South America, Russia, and Kazakhstan in the Commonwealth of Independent States, as well as some countries in Africa, Eastern Europe, and Southeast Asia. We participate in exhibitions in these regions and visit local customers to understand the needs of customers in different regions and maintain stable cooperative relationships.

Main products

Underground mining equipment(underground mining scooptram, underground mining truck, underground service vehicle, underground electric locomotive, rock splitter, and underground concrete mixer truck, etc.), mineral processing equipment(crush, feeder, leaching tank, vibrating screen, and shaking table, etc.)) and related accessories and spare parts(engine, converter, transmission, axle, tire, filter, etc.).You can check them on our homepage or contact us for details.

Patents and certifications

We have some practical patents for our products and have passed CE, ISO9001, and other authoritative certifications. You can check them on our homepage or contact us for details.

Equipment maintenance

Underground mining equipment requires regular maintenance to ensure optimal performance and safety. This may involve routine inspections, lubrication, replacement of parts(we recommend you purchase some parts along with the equipment for convenient replacement and low shipping), and repairs as needed. We can provide online maintenance guidelines and support.

More information

To learn more about our company’s information and products, you can follow us on Facebook, Pinterest, YouTube, LinkedIn, Instagram, and VK. You can also browse our website(www.qxdali.com) or contact us through WhatsApp, WeChat, and Telegram.

-

UK-6WX Underground Scissor Lift: The Perfect Solution for Lifting Heavy Loads

The UK-6WX Scissor Lift is a high-performance lifting equipment that is designed to meet the demands of heavy-duty lifting in underground spaces. With a lifting capacity of up to 3.5 meters, this scissor lift is ideal for a wide range of applications, including mining, construction, and maintenance operations.

One of the key features of the UK-6WX Scissor Lift is its compact design that allows it to fit into tight spaces. This makes it the perfect solution for lifting heavy loads in underground spaces where there is limited room for maneuvering. The lift is also equipped with a powerful hydraulic system that provides smooth and efficient lifting, making it easy to handle heavy loads with precision and control.

The UK-6WX Scissor Lift is built to withstand the harsh conditions of underground environments. It is constructed with high-quality materials that are resistant to corrosion, wear, and tear.

In addition to its impressive lifting capacity, the UK-6WX Scissor Lift is also designed for ease of use. It features a user-friendly control panel that allows operators to adjust the lift’s height and direction with ease.

Overall, the UK-6WX Scissor Lift is a reliable and efficient lifting solution for underground operations. Its compact design, powerful hydraulic system, and safety features make it the perfect choice for lifting heavy loads in tight spaces. Whether you are working in mining, construction, or maintenance, the UK-6WX Scissor Lift is sure to meet your lifting needs.

-

Durable Mining Machinery: The Underground Lift Table Mining Scissor-Lift Platform Vehicle

Introduction:

In the mining industry, the need for durable and reliable machinery is crucial to ensure efficient and safe operations. One such machinery that plays a vital role in underground mining is the lift table mining scissor-lift platform vehicle. This article explores the importance of durable mining machinery, particularly focusing on the underground lift table mining scissor-lift platform vehicle.1. Understanding the Underground Lift Table Mining Scissor-Lift Platform Vehicle:

The underground lift table mining scissor-lift platform vehicle is a specialized piece of equipment designed for transporting heavy loads and personnel in underground mining environments. It features a scissor-lift mechanism that enables vertical movement, providing access to different levels within the mine. This vehicle is specifically built to withstand the harsh conditions and challenges encountered in underground mining operations.2. Durability: A Critical Factor in Mining Machinery:

Durability is a critical factor in mining machinery due to the demanding nature of mining operations. Underground mining environments are characterized by extreme temperatures, high humidity, dust, and vibrations, which can put significant strain on equipment. Durable machinery can withstand these conditions, ensuring minimal downtime and reducing maintenance costs.3. Importance of Durable Lift Table Mining Scissor-Lift Platform Vehicle:

The lift table mining scissor-lift platform vehicle’s durability is of utmost importance in underground mining. It must withstand heavy loads, constant movement, and exposure to dust and debris. A durable vehicle ensures the efficient transportation of personnel and materials, reducing the risk of accidents and increasing productivity.4. Key Features of a Durable Lift Table Mining Scissor-Lift Platform Vehicle:

a. Robust Construction: The vehicle should be constructed using high-quality materials that can withstand the rugged mining environment.

b. Corrosion Resistance: Underground mining environments often have high levels of moisture and corrosive elements. A durable vehicle must have effective corrosion-resistant coatings.

c. Enhanced Safety Features: Durable vehicles should be equipped with safety features such as emergency stop buttons, anti-slip surfaces, and reliable braking systems to ensure the safety of personnel.

d. Easy Maintenance: Durable machinery should be designed for easy maintenance, allowing for regular inspections and repairs without causing significant downtime.5. Benefits of Using Durable Mining Machinery:

a. Increased Productivity: Durable machinery minimizes downtime due to breakdowns or maintenance, ensuring continuous operations and increased productivity.

b. Cost Savings: Investing in durable machinery reduces repair and replacement costs, leading to long-term cost savings.

c. Enhanced Safety: Durable machinery provides a safe working environment, reducing the risk of accidents and injuries to personnel.Conclusion:

In the demanding mining industry, the durability of machinery is paramount. The underground lift table mining scissor-lift platform vehicle plays a crucial role in underground mining operations, providing safe and efficient transportation of personnel and materials. Choosing a durable vehicle ensures uninterrupted operations, increased productivity, and a safer working environment. -

Underground Scissor Lift

The DALI Scissor Lift with lifting capacity up to 4.5 tonnes and max platform height of 4.5 m is designed to provide a safe work platform for all kinds of installation works in tunnels up to 6.5 m (21 feet) high. Typical applications are fan installations, ventilation ducting, electrification works and piping for air and water services. Four platform sizes with side shift provide complete drift coverage from single setup practically in all kinds of mine headings.

-

Underground mining scissor lift rigid basket scissor lift platform truck for mining

The UK-6WX low-profile articulated underground scissor lift is a game-changer in the mining industry. With its innovative design and advanced features, this scissor lift is set to optimize the way mining operations are conducted.

One of the key features of the UK-6WX scissor lift is its superior productivity. The lift is designed to provide efficient and reliable transportation of personnel, materials, and explosives underground. Its low-profile design allows it to navigate tight spaces and rough terrain with ease, making it the perfect solution for underground mining operations.

In addition to its productivity, the UK-6WX scissor lift also offers unparalleled comfort for operators. The vehicle is equipped with ergonomic seats, and advanced safety features to ensure a comfortable and closed working environment for operators.

Safety is a top priority for Dali Company, and the UK-6WX scissor lift is no exception. The vehicle is equipped with state-of-the-art safety features to ensure the safety of operators and personnel underground.

In addition to the UK-6WX scissor lift, Dali Company also offers a range of other underground service vehicles to meet the diverse needs of mining operations. From personnel transport vehicles to explosive transport vehicles and material transport vehicles, Dali Company has the equipment and expertise to support mining operations of all sizes.