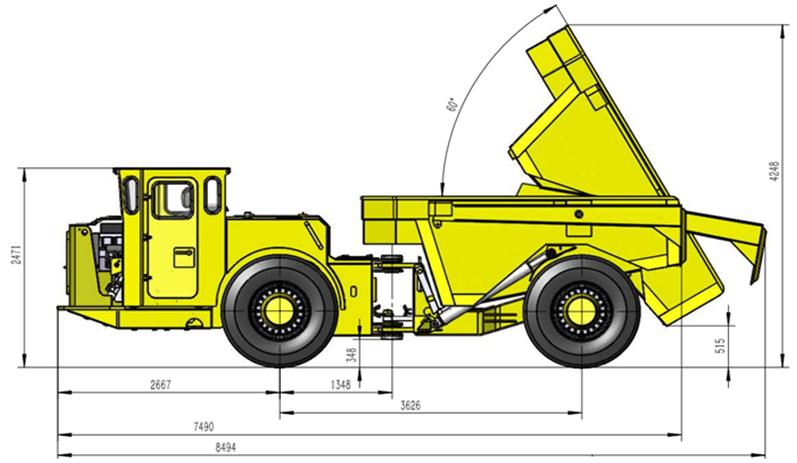

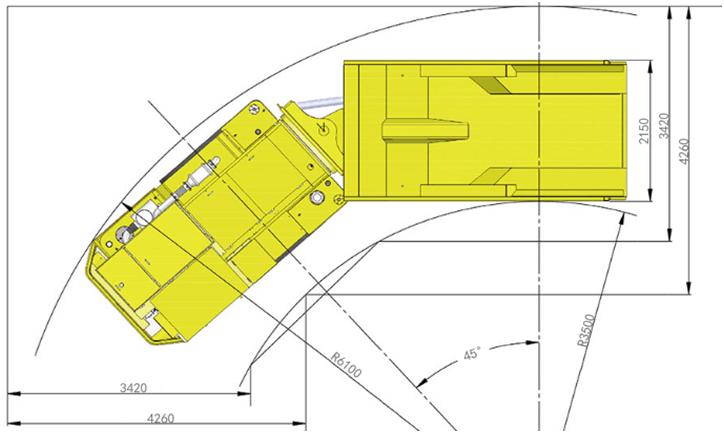

UK-15 Low profile 4 wheel underground mining dump truck

The spring seat in operator’s compartment offers comfort in applications which require both forward and reverse operation. The equipment has joystick steering and dump box control. Visibility from the operator’s compartment has been improved e.g. with a perforated box front edge and optional reverse camera. Color-coded three-point of contact access system with fold-out ladders and handles offers easy access to the maintenance areas on top of the truck. Efficient and long-life LED lights improve visibility

Power Train

Engine

Model……………………DEUTZ BF6M1013EC 165kw

Type..............................water-cooled / turbo charge

Purifier…………………..Catalytic purifier with silencer

Torque converter

Brand…………………….DANA

Model…………………….C273

Transmission

Brand…………………….DANA

Model…………………….RT32421

Wheel & Tire

Wheel rim…………………14.0

Tire………………………..17.5-25 PR 24 L-5S

Material……………………Nylon

Frame

Connection form…………Articulating

Material……………………High manganese steel

Axle

Brand…………………….DANA

Model……………………16D2149

Type……………………..Rigid planetary axle

Front axle(empty)………10100KG

Rear axle(empty)……….6200KG

Front axle(loaded)………16100KG

Rear axle(loaded)……….15200KG

Differential(front axle)…..NO-SPIN

Differential(Rear axle)…..Standard

Hydraulic

Duplex pump……………..PERMCO

Steering wheel……………PARKER

Oil filling valve……………Rexroth

Pedal……………………..MICO

Multiway valve………......PARKER

Braking Pump……………DEUTZ

Electric

Working voltage…………..24V DC

Battery…………………….12V*2

Alternator………………….55A/28V

Starting motor…………….5.5KW/24V

Headlight………………….LED 2*40w

Rear light………………….LED 2*40w

Brakes

Service brakes are spring applied; hydraulically operated multi disc wet brakes on all wheels. Two independent circuits: one for the front and one for the rear axle. Service brakes also function as an emergency and parking brake. Brake system performance complies with requirements of EN ISO 3450, AS2958.1 and SABS 1589.

All DALI underground mining dump trucks are designed to operate fully loaded and at high speeds on long spiral haulage ways with up to 25% gradients.

Advantages

●Small envelope size and turning radius enable easy navigation

●Excellent payload capacity improves productivity and provides a low cost per hauled ton

●Two-pass truck loading with DALI WJ-3 LHD underground loader optimizes the ore-moving process

●Ground-level daily maintenance enables safer servicing