Underground personnel transportation carriers are vehicles used to transport people in underground mines, tunnels, and other underground settings. These carriers are designed to provide a safe and comfortable means of transportation for workers who need to travel long distances underground. They are typically equipped with safety features such as roll bars, seat belts, and emergency stop buttons to ensure the safety of passengers. Some carriers are also equipped with air conditioning and heating systems to provide a comfortable environment for workers. These vehicles can be operated by a driver or remotely controlled, depending on the specific application. Underground personnel transportation carriers are an essential part of underground mining operations and are used to transport workers, equipment, and supplies to and from the work site.

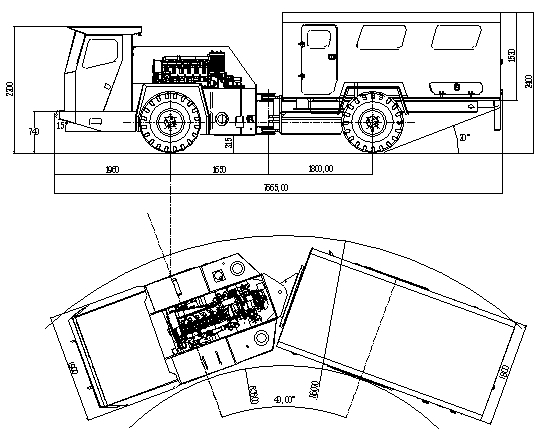

The underground personnel carrier has a good climbing ability, strong carrying capacity, and excellent stability. It is widely used in underground transportation of personnel, materials, and equipment, and is an indispensable tool for mine and tunnel construction.

Application range

The personnel transporter is typically trackless, which means it does not require a fixed rail system to operate. Instead, it can move freely through the mine using a combination of electric motors, hydraulic systems, and other advanced technologies. This allows for greater flexibility and mobility in navigating the complex underground environment.

One of the key features of the personnel transporter is its ability to reach multi-level destinations through the mine ramp system. This is achieved through a combination of advanced navigation systems and powerful propulsion systems that can handle steep inclines and rough terrain. The result is a highly efficient and reliable method of transporting large numbers of personnel to and from the work site.

In addition to its primary function as a personnel transporter, the mining vehicle product line also includes a range of other vehicles designed for specific mining applications. These may include utility vehicles, drill rigs, and other specialized equipment that can help to improve efficiency and safety in the mining process.

Overall, the personnel transporter is an essential component of any modern mining operation. With its advanced technology and flexible design, it provides a safe and efficient means of transporting personnel and equipment through the challenging underground environment.

Advantages of our personnel carrier

Advanced safety features. Safety is a top priority for underground personnel carriers. The vehicle is equipped with a reverse alarm, fire extinguisher, emergency stop button, and other safety devices to ensure the safety of the driver and passengers.In addition, regular maintenance and inspection of the vehicle are necessary to ensure its safe and efficient operation. Proper training for the driver is also essential to ensure safe and responsible driving.

Real-time monitoring and control system for improved safety and efficiency.

Customizable seating arrangements to accommodate different passenger and material needs.

Low noise and vibration for a comfortable ride.

Weather-resistant design for reliable operation in harsh conditions.

Low operating costs and high reliability for maximum uptime.

Flexible design options to meet specific customer requirements.

Overall, the underground personnel carrier is a reliable and efficient service vehicle that plays a crucial role in underground mining and tunnel construction projects.

Our company

Dali mining machinery was founded on May 17, 2001, located in Qixia Private Economic Park, covering an area of 105,000 square meters. It is a well-known professional manufacturer of mineral processing machinery and trackless machinery and equipment in China. The company has an annual production capacity of more than 300 sets of large-scale mine trackless machinery equipment and an annual output value of 60 million beneficiation machinery and equipment.

The main products of mineral processing machinery are ball mills, vertical mills, classifiers, flotation machines, stirring tanks, and thickeners, six series of dozens of varieties of products. The main products of trackless machinery are 0.6 m3, 1 m3,1.5 m3, 2 m3 of electric and diesel loaders ; 3 m3, 4 m3, 6 m3 of diesel loaders; 6 tons, 8 tons, 10 tons, 12 tons, 15 tons, 20 tons, 30 tons, 40 tons dumper truck; mobile crusher; various service vehicles such as vehicle chassis, fuel vehicles, underground lifting platforms, blasting equipment vehicles and underground concrete mixer.

Our products are widely exported to CIS countries(Russia, Kazakhstan, Uzbekistan, etc), South America, Southeast Asia and Mongolia. We have experienced technical R&D personnel of mineral processing and mining equipment and reliable multilingual business personnel. In Russia and Peru, we have long-term cooperative agent companies that can provide us with goods preparation, maintenance and other services, which is more convenient for our cooperation with local customers.

A brief introduction to the development of our company

1998 Leasing plant and preparing to establish a company to undertake mine equipment maintenance business

2003 The first plant was put into operation, and the ball mill, classifier and flotation machine were developed successfully

2005 Undertake orders of more than 10 million complete sets of mineral processing equipment from a single customer

2007 The second plant is put into operation and the first LHD loader is developed

2009 The first WJD-1 electric loader is offline

2010 Complete trademark registration, and the first WJ-1 diesel LHD loader is offline

2013 It passed ISO9001-2008 certification for the first time, and the first WJD-2lhd loader was successfully developed

2014 Through the certification of “Safety Mark for Mining Products”, WJD-1S, WJD-1C and WJ-2 have been successfully developed

2015 The first batch of patents were successfully declared, and WJD-1.5 and WJ-0.6 were successfully developed

2016 The third production area was put into production, and WJD-0.6 LHD loader and UK-15 Dumper truck were successfully developed

2017 Company development of foreign trade business, WK-15 export to Russia, intelligent remote control system implementation

2018 Successful development of UK-12 Dumper truck

2019 Passed ISO9001-2015 certification, and WSJ-400YK, WJ-3 and underground concrete mixer were successfully developed

2020 WJD-1T, WK-6, WK-20, underground Bus , lifting platform offline

2021 In the 20th anniversary of the founding of the company, two production lines of mining equipment and mineral processing equipment were formed, with more than 100 varieties of product business