4 ton Mining LHD Underground Loader WJ-2

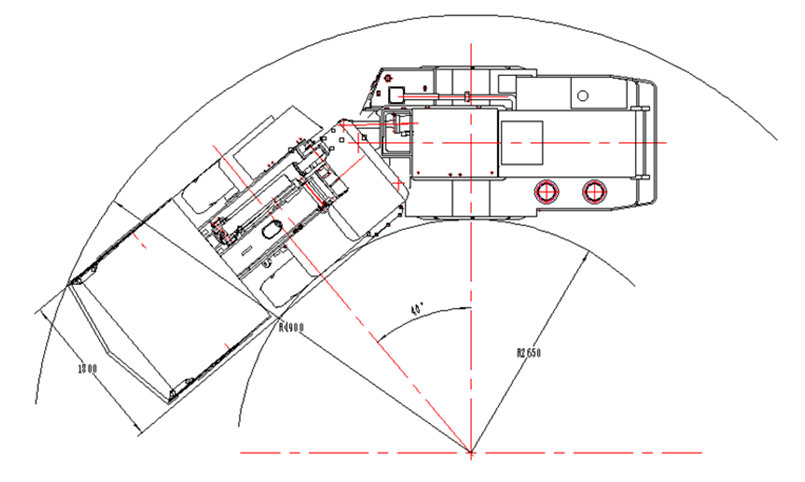

The WJ-2 is full of features to help mines maximize tonnes and minimize extraction costs. Engineered to optimize machine width, length and turning radius, enabling operation in narrower tunnels for less dilution and lower operational costs.

Technical Specification

|

Dimension |

Capacity |

||

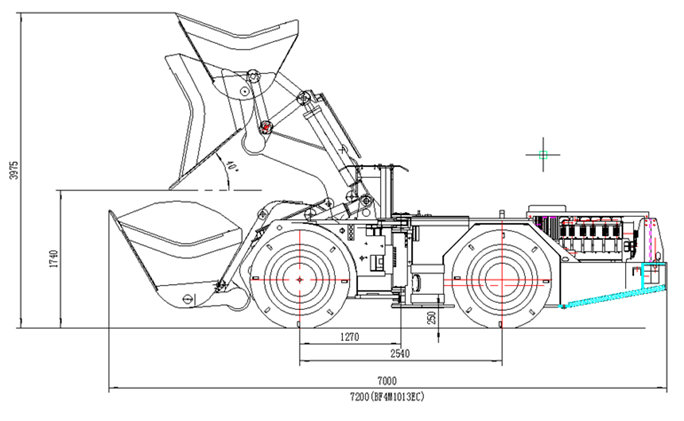

| Tramming Size | 7000*1800*2080mm | Standard Bucket | 2m3 |

| Min Ground Clearance | 250mm | Payload | 4000KG |

| Max Lift Height | 3975mm | Max Breakout Force | 85KN |

| Max Unloading Height | 1740mm | Max Traction | 104KN |

| Climing Ability(Laden) | 20° | ||

|

Performance |

Weight |

||

| Speed | 0~17.4km/h | Operation Weight | 13500kg |

| Boom Raising Time | ≤6.3s | Laden Weight | 17500kg |

| Boom Lowering Time | ≤3.6s | Front Axle(Empty) | 5100kg |

| Dumping Time | ≤4.0s | Rear axle(Empty) | 8400kg |

| Oscilation Angle | ±8° | Front Axle(laden) | 9600KG |

Power Train

|

Engine |

Transmission |

||

| Brand & Model | Deutz F6L914(BF4M1013EC option) | Torque Converter | DANA C270 |

| Type | Air-Cool | Gearbox | RT32000 |

| Power | 83kw / 2300rpm |

Axle |

|

| Cylinders | 6 In line | Brand | CMG |

| Emission | EURO II / Tier 2 | Model | CY-2J |

| Purifier Brand | ECS(Canada) | Type | Rigid planetary axle |

| Purifier Type | Catalytic purifier with silencer | ||

Advantages

●Proven design for narrow-vein mining

●Low operating weight reduces fuel consumption and extends tire life

●Small envelope size and turning radius enable easy navigation in narrow veins

●Ground-level daily maintenance enables safer servicing

The operator's compartment is ROPS and FOPS certified to improve safety underground, and efficient LED lights improve visibility. Safety can be further improve by equipping the loader with a fire suppression system, radio remote control and recovery kit.

Service brakes are hydraulically operated multidisc wet brakes on all wheels. Two independent circuits: one for the front and one for the rear axle. Parking brake is spring applied, hydraulically released dry disk brake affecting on the front axles drive line In case of a sudden pressure drop in brake hydraulics the parking brake functions as an emergency brake. Brake system performance complies with requirements of EN ISO 3450, AS2958.1 and SABS 1589