1.0m3 underground mining Load Haul Dump wheel loader WJ-1

DALI WJ-1 is a new compact and lightweight 2-metric-ton-capacity Load Haul Dump (LHD) for narrow vein mining. Best payload to own weight ratio in its class. It offers both reduced dilution, better flexibility and operator safety when working in narrow vein operations. The WJ-1 is full of features to help mines maximize tonnes and minimize extraction costs. Engineered to optimize machine width, length and turning radius, enabling operation in narrower tunnels for less dilution and lower operational costs.

Technical Specification

|

Dimension |

Capacity |

||

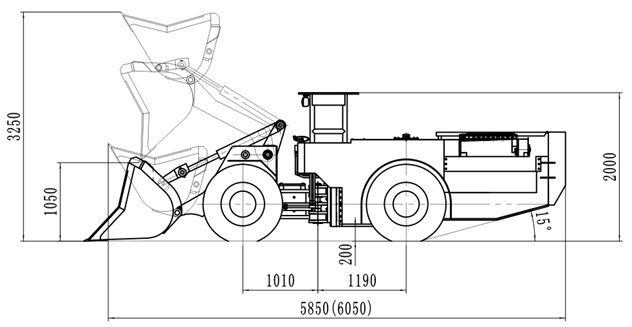

| Tramming Size |

5850(6050)*1300*2000

mm |

Standard Bucket | 1m3(1.5yards) |

| Min Ground Clearance | 200mm | Payload | 2000KG |

| Max Lift Height | 3250mm | Max Breakout Force | 45KN |

| Max Unloading Height | 1050mm | Max Traction | 50KN |

| Climing Ability(Laden) | 20° | ||

|

Performance |

Weight |

||

| Speed | 0~8km/h | Operation Weight | 6750kg |

| Boom Raising Time | ≤3.8s | Laden Weight | 8750kg |

| Boom Lowering Time | ≤1.9s | Front Axle(Empty) | 2230kg |

| Dumping Time | ≤2.5s | Rear axle(Empty) | 4520kg |

| Oscilation Angle | ±8° | Front Axle(laden) | 5050KG |

Power Train

|

Engine |

Transmission |

||

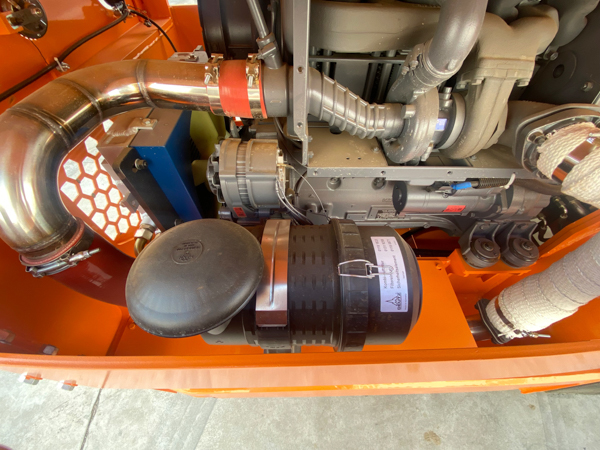

| Brand & Model | DEUTZ BF4L914 / 66kw | Type | Hydrostatic |

| Emission | EURO II / Tier 2 | Pump | DANFOSS T90 |

| Air Filter | Two stage & dry type | Motor | SAUER MV23 |

| Purifier Type |

Catalytic purifier with

silencer

|

Transfer Case | DLWJ-1 |

|

Tire

|

Axle |

||

| Model | 10.00-20 PR14 L-4S | Brand | DALI |

| Material | Nylon | Model | PC-15-B F/R |

| Type | Rigid planetary axle | ||

Structure

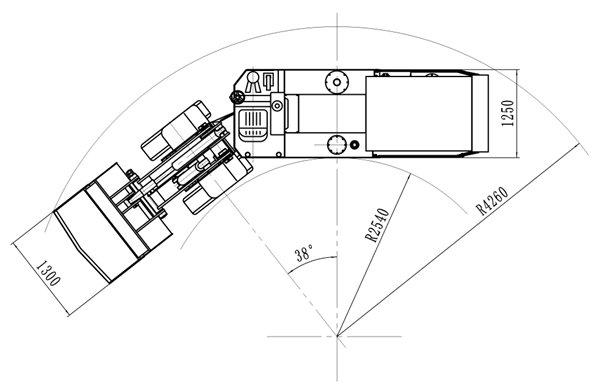

♦The frames are articulated with 38° steering angle.

♦Ergonomics Canopy with side seat to provide good bi-directional view of operation.

♦An enhanced boom and load frame geometry optimizes digging performance.

Operation Comfort & Safty

♦4 wheels driving & braking.

♦Combination design of parking brake & working brake ensures good braking performance. Braking model is SAHR(spring applied, hydraulic release).

♦Front axle is equipped NO-SPIN differential. While rear is ANTI-SLIP.

♦Hydraulic joystick control for working to reduce the labor intensity of the driver.

♦Low vibration level in cab

Early Warning & Maintenance

♦Automatic alarm system for oil temperature, oil pressure and electrical system.

Enegy-saving & Enviroment Friendly

♦Germany Deutz engine with air-cooling and turbocharging, powerful and low-consumption.

♦Canada ECS catalytic purifier with silencer, which greatly reduces air and noise pollution in working laneway.

Business type

We are a self-owned factory with years of production and export experience.

Company location

Our factory is situated in Yantai, Shandong Province, China, a location that boasts both a harbor and an international airport. Additionally, it enjoys close proximity to Qingdao Airport and harbor, providing our customers with great convenience for visiting and shipping goods.

Employee headcount

We have over 100 employees, including experienced engineers (R&D, quality inspection, and after-sales), workers, and salespersons. Additionally, we have local salespersons in some countries.

Main markets

Our products are mainly sold to Peru, Chile, Bolivia, Colombia in South America, Russia, and Kazakhstan in the Commonwealth of Independent States, as well as some countries in Africa, Eastern Europe, and Southeast Asia. We participate in exhibitions in these regions and visit local customers to understand the needs of customers in different regions and maintain stable cooperative relationships.

Main products

Underground mining equipment(underground mining scooptram, underground mining truck, underground service vehicle, underground electric locomotive, rock splitter, and underground concrete mixer truck, etc.), mineral processing equipment(crush, feeder, leaching tank, vibrating screen, and shaking table, etc.)) and related accessories and spare parts(engine, converter, transmission, axle, tire, filter, etc.).You can check them on our homepage or contact us for details.

Patents and certifications

We have some practical patents for our products and have passed CE, ISO9001, and other authoritative certifications. You can check them on our homepage or contact us for details.

Equipment maintenance

Underground mining equipment requires regular maintenance to ensure optimal performance and safety. This may involve routine inspections, lubrication, replacement of parts(we recommend you purchase some parts along with the equipment for convenient replacement and low shipping), and repairs as needed. We can provide online maintenance guidelines and support.

More information

To learn more about our company's information and products, you can follow us on Facebook, Pinterest, YouTube, LinkedIn, Instagram, and VK. You can also browse our website(www.qxdali.com) or contact us through WhatsApp, WeChat, and Telegram.