DALI WJ-3 Mining Loader——The Ultimate Workhorse for Your Mining Operations

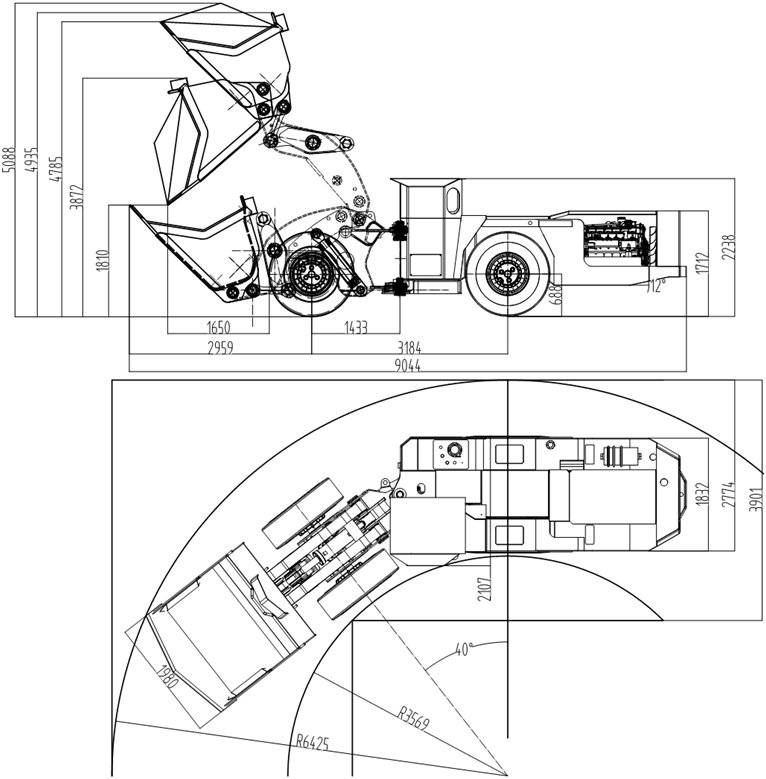

DALI WJ-3 is an underground LHD Loader that features a tramming capacity of 7 metric tons and our latest LHD technology to provide maximum performance in the toughest underground applications. The articulated WJ-3 carries 7 ton of payload in its bucket, that is sized at 3 m3 (SAE heaped). The vehicle is only 9044 mm long in driving position, 2,107 mm wide at the cab and 2,238 mm high at the cab when loaded. This meets the demands of applications like large narrow vein and small mass mining operations.

Technical Specification

|

Dimension |

Capacity |

||

| Tramming Size | 9044*1980*2238mm | Standard Bucket | 3m3 |

| Min Ground Clearance | 315mm |

Tramming capacity

|

7000KG |

| Max Lift Height | 4935mm |

Maximum breakout force

|

131KN

|

| Max Unloading Height | 1810mm |

Maximum Tractiom

|

170 KN

|

| Climing Ability(Laden) | 20° | ||

|

Performance |

Weight |

||

|

3 rd Gear Speed

|

0~18.4km/h | Operation Weight | 17600kg |

| Boom Raising Time | ≤6.5 s | Laden Weight | 24600kg |

| Boom Lowering Time | ≤3.2s | Front Axle(Empty) |

6790kg

|

| Dumping Time | ≤3.7 s | Rear axle(Empty) |

10810kg

|

| Oscilation Angle | ±8° | Front Axle(laden) |

14100KG

|

Power Train

|

Engine |

Transmission |

||

| Brand & Model | Deutz BF6M1013EC | Torque Converter | DANA C273 |

| Type | Water-cooled / Turbocharged | Gearbox | RT32360 |

| Power | 165kw / 2300rpm |

Axle |

|

| Cylinders | 6 In line | Brand | DANA |

| Emission |

EU II, US T2

|

Model |

16D2149

|

| Purifier Brand | ECS(Canada) | Type | Rigid planetary axle |

| Purifier Type | Catalytic purifier with silencer | ||

Advantages

●ROPS/FOPS-certified operator canopy and optional enclosed cabin improves safety

●DALI Intelligent Control system monitors all loader parameters, expediting troubleshooting and minimizing unscheduled downtime

●Low emission engine to ensure sustainable mining

●Ground-level daily maintenance enables safer servicing

Intelligent Control System

To minimize the need to move around the machine or use special tools, the 5.7” touch screen color display in the operator’s compartment provides service information, easy system diagnostics and alarm log files. An automatic brake test with diagnostics and logging can also be performed from the display.

Automatic Central Lubrication

The central lubrication system, a standard feature in the DALI WJ-3, optimizes grease consumption and extends the life of the bushes and bearings. Activated by DALI Intelligent Control System when the parking brake is released, hard to reach areas are well lubricated and service time is reduced.

Safety Onboard

All required daily checks can be done from the ground level. Energy isolation can be achieved with a lockable main switch, and standard onboard wheel chocks can be used to ensure the machine remains stationary. Maintenance access to the top of the machine includes three-point contact handles and anti-slip steps. Optionally available safety rails on the rear of the machine reduce risks of falling.